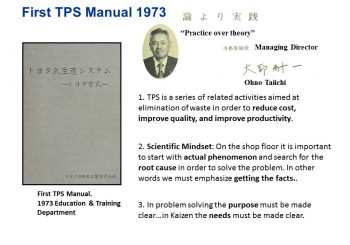

Call it kaizen or continuous improvement or whatever term you prefer. In the end if you don't deliver results you won't be in business for long. The two pillars of the Toyota system are respect for people and continuous improvement for this reason. Processes, equipment, tools, or assets don't improve on their own. It takes the structured work of teams to drive and sustain impro...

Read More